Introduction to Epoxy Resin

Epoxy resin serves as the fundamental base material for all System epoxy compounds. This remarkable substance begins as a clear, pale yellow, low-viscosity liquid that transforms into an incredibly strong, waterproof solid when properly cured. Its unique chemical structure allows for exceptional versatility across countless applications, from industrial coatings to artistic creations.

Core Characteristics of Epoxy Resin

At its essence, epoxy resin is a thermosetting polymer that achieves its full potential when blended with specific hardeners. The curing process creates cross-linked molecular chains that result in:

- Superior mechanical strength

- Excellent moisture and chemical resistance

- Outstanding adhesion properties

- Long-term durability

The resin’s low viscosity before curing ensures excellent penetration and wetting characteristics, making it ideal for coating porous materials or bonding dissimilar substrates.

Customizable Performance Through Hardeners

The true magic of epoxy resin lies in its ability to produce different performance characteristics based on the hardener selection. Our system offers four specialized hardeners:

- Standard Hardener (5:1 ratio)

- Ideal for general-purpose applications

- Cures at room temperature within 24 hours

- Creates high-strength bonds perfect for structural applications

- Can be modified with various fillers and additives

- Fast Hardener (5:1 ratio)

- Accelerated curing time (4-6 hours at room temperature)

- Excellent for production environments requiring quick turnaround

- Maintains all the beneficial properties of standard epoxy

- Slow Hardener (3:1 ratio)

- Extended working time (90+ minutes pot life)

- Produces crystal-clear finishes perfect for wood coatings

- Resists blushing even in high humidity conditions

- Extra Slow Hardener (3:1 ratio)

- Specifically formulated for hot/humid environments

- Provides extended working time at elevated temperatures

- Maintains clarity and physical properties in challenging conditions

Limitless Modification Possibilities

Our epoxy resin system becomes even more powerful when combined with Ochcho’s complete line of fillers, additives, and pigments. This modular approach allows users to create customized formulations for specific applications:

- Pigments: Transform the clear resin into any color for decorative or functional purposes

- Fillers: Add strength, thickness, or special properties like fire resistance

- Additives: Modify viscosity, cure speed, or surface characteristics

Common modifications include:

- High-strength fairing compounds for marine applications

- Non-skid flooring additives

- UV-resistant formulations for outdoor use

- Low-friction coatings for industrial equipment

Superior Performance in Critical Applications

Structural Bonding

When maximum strength matters, our epoxy resin delivers:

- Tensile strength exceeding 8,000 psi

- Shear strength over 2,000 psi

- Excellent fatigue resistance

- Minimal shrinkage during cure

Protective Coatings

For surfaces requiring durable protection:

- Forms an impermeable moisture barrier

- Resists chemicals including acids, alkalis, and solvents

- Can be applied in thicknesses from microns to inches

- Maintains flexibility to prevent cracking

Fiberglass Reinforcement

The ideal matrix material for fiberglass composites:

- Excellent fiber wet-out characteristics

- Strong interfacial bonding with glass fibers

- Can be used for hand lay-up or vacuum infusion

- Creates lightweight, high-strength structures

Application Techniques for Professional Results

Achieving optimal performance requires proper application methods:

- Surface Preparation

- Clean and degrease all surfaces

- Light abrasion improves adhesion

- Ensure proper temperature (60-90°F ideal)

- Mixing

- Measure components precisely

- Mix thoroughly for at least 3 minutes

- Use clean containers and tools

- Application

- Apply within working time window

- Use appropriate tools (brush, roller, squeegee)

- Maintain proper film thickness

- Curing

- Allow full cure before stressing

- Post-cure at elevated temperatures for maximum properties

- Avoid exposure to moisture during cure

Real-World Success Stories

Our epoxy resin system has proven its value across diverse industries:

Marine Applications

- Hull repairs and reinforcement

- Deck non-skid coatings

- Underwater bonding

Industrial Maintenance

- Chemical tank linings

- Flooring systems

- Equipment repairs

Woodworking

- Bar tops and table finishes

- Musical instrument construction

- Decorative inlays

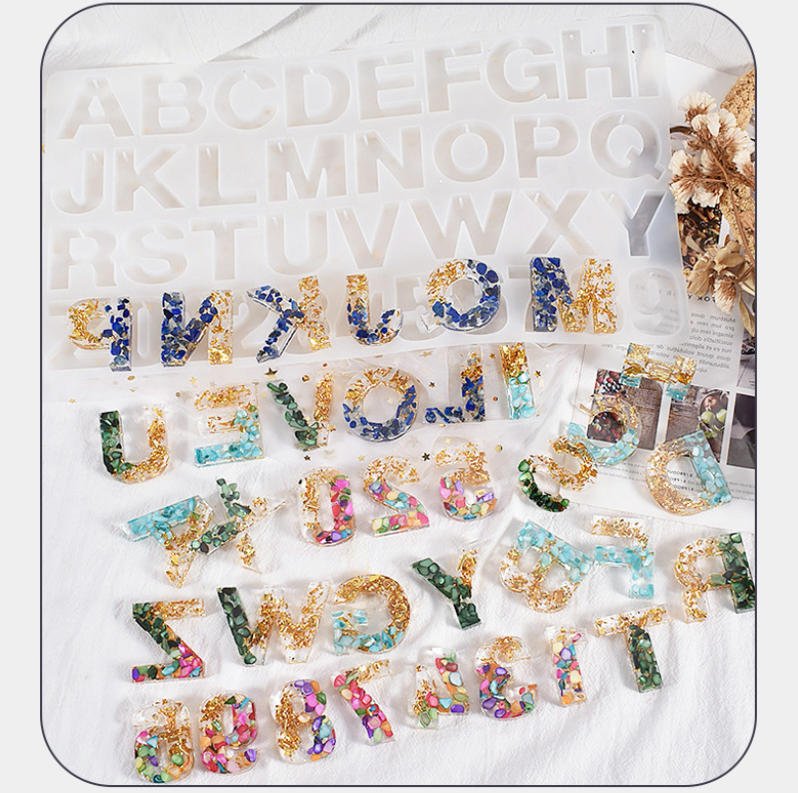

Creative Arts

- Jewelry making

- Sculpture

- Pigmented art pieces

Technical Support and Resources

We stand behind our products with comprehensive support:

- Detailed technical data sheets

- Application guides for various uses

- Troubleshooting assistance

- Custom formulation advice

Conclusion

As the foundation of all System epoxy compounds, our epoxy resin provides unparalleled versatility combined with reliable performance. Whether you need structural bonding strength, protective coatings, or customized formulations, this remarkable material delivers consistent results across countless applications. Its ability to be precisely tailored through hardener selection and modifications makes it the ideal choice for professionals and DIY enthusiasts alike.

By understanding the fundamental properties and proper application techniques, users can unlock the full potential of epoxy resin to solve even the most challenging material requirements.